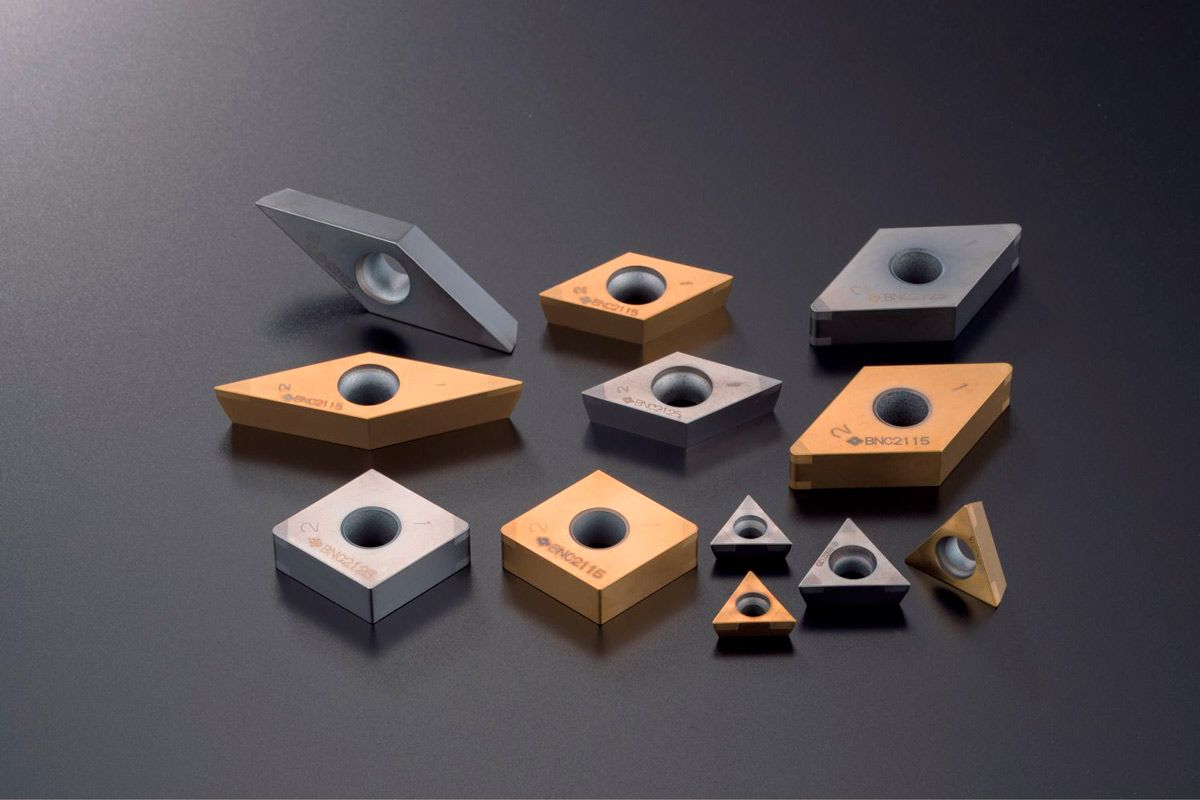

The BN1000 tool is a high-performance tool made from a exceptionally durable CBN (cubic boron nitride) material. This specific composition allows it to achieve exceedingly smooth surfaces during machining, which is particularly critical when addressing surface finish issues.

Benefits:

Superior Surface Finish: Thanks to the CBN material's high hardness and abrasion resistance, very precise and uniform surfaces can be produced. This is particularly important in applications requiring a high surface finish to minimize friction or meet optical requirements.

Enhanced Wear Resistance: The BN1000 offers exceptional wear resistance, meaning it lasts longer even under intensive use and needs to be replaced less often. This reduces maintenance costs and increases productivity.

Stable Machining: The combination of high hardness and wear resistance enables stable machining, even at high cutting speeds. This results in a consistently high surface finish throughout the entire machining process.

Adaptability: The BN1000 can be used in a variety of applications, from continuous cutting to interrupted cutting. It is particularly well-suited for machining hardened steels and offers high fracture toughness, making it ideal for demanding machining tasks.

By using BN1000, customers can effectively address their surface finish issues by achieving a consistently high surface quality while increasing machining efficiency. This leads to improved product quality and reduces the need for subsequent machining steps, which ultimately lowers overall costs and increases productivity.

More details soonHaven't found what you're looking for?

Then please send an e-mail with a description of your optimization requirements to: turning [at] sumitomotool [punkt] com