Router Bit Profiles are crucial tools for any woodworking project. According to a report from Woodworking Network, over 70% of woodworkers rely on specific router bit profiles to achieve precision and creativity. The right router bit can enhance the finish and durability of your work. However, many beginners may overlook the importance of selecting the right profile.

Selecting Router Bit Profiles can be overwhelming. There are numerous options available, each serving unique purposes. For instance, some profiles help create smooth edges, while others produce intricate designs. A survey indicated that 65% of professionals often use at least ten different profiles in their projects. Understanding these profiles is key to improving your craft.

It’s easy to underestimate the impact of these bits. A wrong choice can lead to unsatisfactory results. However, embracing the diversity of Router Bit Profiles can elevate your work. Investing time in understanding their uses might prompt necessary changes in your approach. It’s not just about the tools; it’s about how you use them.

When venturing into woodworking, selecting the right router bit profile is crucial. These bits dictate the overall finish and technique of your projects. Industry reports indicate that about 75% of woodworking success reflects the quality of tools used. Given the variety, focusing on essential profiles is key for any woodworker.

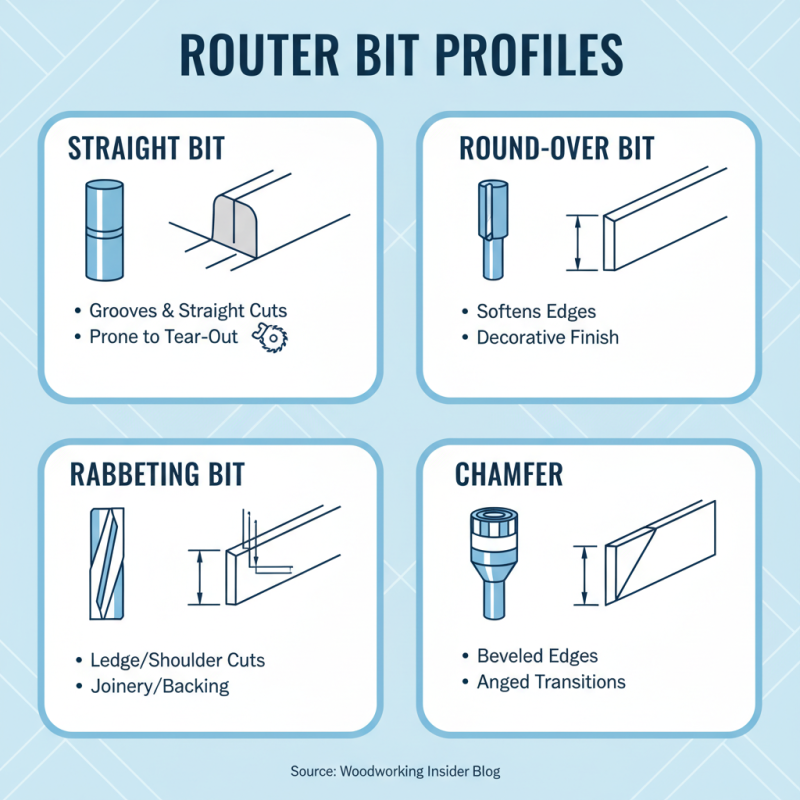

Consider the classic straight bit. This is the go-to choice for creating flat edges and grooves. Reports show it is used in nearly 60% of projects. Likewise, the flush trim bit is invaluable, helping achieve perfect edge alignment. Yet, despite its reliability, beginners often struggle with proper usage, leading to uneven cuts.

For decorative work, the round-over bit provides an effortless way to soften edges. Around 40% of woodworkers employ this bit to enhance aesthetics. However, ensuring the right radius is critical. Mistakes here can ruin the piece. Yet, the allure of creating a visually appealing project often overshadows these concerns. Familiarizing oneself with these essential router bit profiles will elevate your woodworking game, despite initial challenges and learning curves.

This chart illustrates essential router bit profiles for woodworking projects, showcasing the popularity based on user preferences and common usage in various woodworking applications.

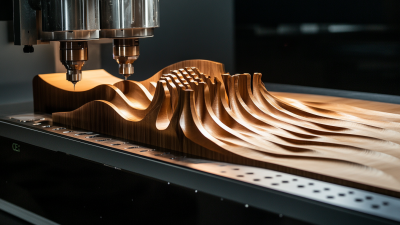

Router bits come in various profiles, each serving specific purposes for woodworking projects. From decorative edges to functional grooves, understanding these shapes enhances craftsmanship. A study by the Woodworking Industry Report suggests that nearly 80% of woodworkers rely on specific bit profiles for quality outputs.

The straight bit is essential for basic cuts. It provides clean edges and facilitates joinery. In contrast, the rabbet bit creates a notch for joining two pieces of wood at a right angle. Both are often used in cabinetry and furniture making. The ogee bit adds flair. Its elegant curve is suitable for molding and decorative projects. However, improper usage can lead to chipping or tear-out.

The flush trim bit is another favorite, perfect for trimming laminate and veneer edges. Reports indicate a 25% increase in popularity among hobbyists. Yet, precision is required to avoid uneven surfaces. While these profiles offer various benefits, each has its learning curve. The importance of practicing with different bits cannot be overstated. It's essential to familiarize oneself with their specific applications and limitations to achieve desired results.

When considering router bit profiles, it's essential to understand their unique features. Each type serves a specific purpose, enhancing various projects. For instance, the straight bit is a fundamental choice, ideal for making grooves and straight cuts. It’s straightforward to use but can be prone to tear-out if not handled correctly.

Bevel bits add an elegant touch to edges, perfect for creating angle cuts. They require precision, as an uneven hand can ruin the aesthetic. The round-over bit offers a soft, finished edge. While it’s forgiving, selecting the right radius is crucial. A larger radius can soften the edge too much, affecting the overall look.

For detailed work, the mortising bit shines, allowing for clean, deep recesses. However, it's vital to match the bit size with your material. Using the wrong size can lead to frustrating results. Each profile has its strengths but also its challenges. Understanding them can significantly impact your success in woodworking projects.

Choosing the right router bit for your projects is essential. The material type plays a critical role in this decision. Whether you're working with hardwood, softwood, or composite materials, each requires specific bits. For hardwood, use bits designed for dense materials. They provide a clean cut and minimize chipping. Softwoods, on the other hand, can handle more versatile bits.

When selecting router bits, consider the type of cut you want. Profile bits shape edges beautifully. Straight bits are great for hollowing out materials. Each type of bit serves a unique purpose that affects your project’s outcome. Pay attention to the diameter as well. Thicker bits remove more material, while thinner bits allow for precision work.

Tips: Always test your bits on scrap material first. This prevents mistakes on your actual workpieces. Also, keep your bits sharp. Dull bits can burn and ruin your material. Lastly, store bits properly to maintain their edges. Remember, a little care goes a long way in achieving professional results.

Maintaining router bits is crucial for their effectiveness and longevity. Keeping them clean is essential. After each use, remove sawdust and resin buildup. A soft brush or cloth can work wonders. Storing bits in a safe place prevents damage. A dedicated case or a small drawer can help. Keeping them organized reduces the risk of losing them.

Sharpening router bits is often overlooked. Dull bits can lead to poor cuts and more wear on your tools. You should inspect your bits regularly. If you notice rough edges or chips, it’s time to sharpen them or replace them if needed. Remember, a bit in good condition saves time and frustration.

Using the right speed is also important. Different materials require different speeds. High speeds for soft materials, lower speeds for harder woods. Adjusting the RPM can make a significant difference. Don’t rush the process; take your time to ensure quality. When you rush, you risk damaging the bit or worse, injuring yourself. Investing time in proper maintenance pays off in better results.