The 137th Canton Fair, held successfully in Guangzhou, showcased the remarkable growth in international participation,

with a record of 288,938 foreign buyers from 219 countries and regions,

reflecting a 17.3% increase compared to the previous edition. Among the industries

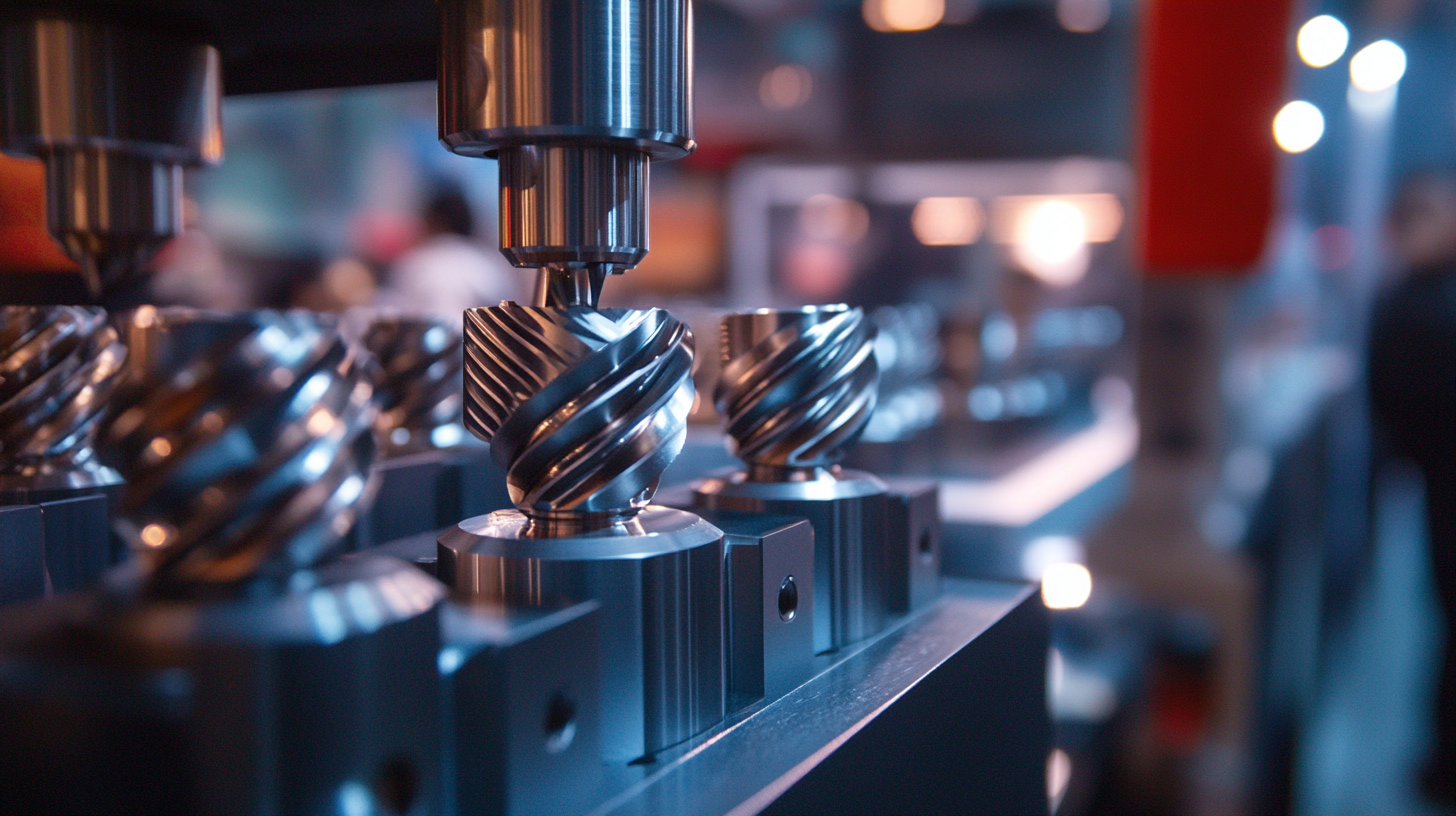

prominently represented, the demand for End Mill Bits has surged significantly, driven by

advancements in manufacturing technology and the increase in global construction projects. According to a recent market

research report, the global end mill market is expected to reach USD 2.8 billion

by 2026, growing at a CAGR of 5.2%. This trend highlights the critical

role that high-quality end mill bits play in various sectors, including aerospace, automotive, and metalworking. As we

examine the top manufacturers in this field from China, insights gained from this prestigious trade event will provide

valuable context for understanding the competitive landscape and innovation driving the end mill industry forward.

The 137th Canton Fair showcased significant trends in the end mill bit manufacturing sector, reflecting a broader shift towards sustainability and innovation. As manufacturers focus on optimizing production processes and minimizing environmental impact, the spotlight is on the introduction of smart manufacturing techniques. This revolutionary approach is not only enhancing efficiency but also aligning with global trends towards green practices. A recent industry report indicates that the implementation of intelligent machinery could reduce production costs by up to 20%, making it a focal point for businesses looking to remain competitive.

In another compelling trend, barrel milling cutters have emerged as a game-changer in the milling industry. Designed for specific applications, these tools provide precision while ensuring simplicity and cost-effectiveness. Industry experts suggest that adopting these tools can improve production capabilities by up to 30% in suitable applications, allowing manufacturers to keep pace with the rising demand for high-quality end mill bits.

**Tips:** Consider investing in automation solutions to streamline your production processes. Explore the potential of cutting-edge milling tools like barrel cutters to enhance precision and efficiency in your operations. Stay informed on emerging industry trends to adapt your strategy effectively.

The 137th Canton Fair has demonstrated remarkable resilience in the face of ongoing global trade challenges, attracting a record number of international buyers. Despite existing tariffs and heightened protectionist measures, the fair saw an impressive turnout that exceeded expectations, reflecting a strong desire for global sourcing and collaboration. Exhibitors were pleasantly surprised by the enthusiasm of visitors, indicating a renewed interest in Chinese products and innovations.

As the world's largest trade event, the Canton Fair serves not only as a platform for showcasing the latest advancements but also as a vital hub for networking and fostering business relationships. The success of the 137th fair underscores the importance of international trade and the ongoing demand for high-quality manufacturing in various sectors. This year, with an expanded thematic focus on innovation and sustainability, the fair is positioning itself as a leader in adapting to the changing global market dynamics.

The 137th Canton Fair showcased a plethora of manufacturers with significant export intentions, particularly in the end mill bit sector. As global demand for precision cutting tools rises, manufacturers from China are increasingly focused on enhancing their export capabilities. According to a report by Market Research Future, the global end mill market is anticipated to reach approximately $6 billion by 2025, growing at a CAGR of 5.3%. This growth is attributed to the expanding manufacturing sector and the rising demand for high-efficiency cutting tools.

At the trade fair, companies displayed their latest innovations, emphasizing the importance of quality and advanced metallurgy in their products. Manufacturers such as Guhring and Secotools have demonstrated the effectiveness of using carbide and cobalt blends in end mills, which significantly extend tool life and cutting performance.

The Canton Fair serves as a critical platform for these manufacturers to establish international partnerships, as 70% of attendees indicated interest in sourcing high-quality end mills for diverse applications ranging from aerospace to automotive industries. This momentum reflects a robust commitment to meet the global market's burgeoning needs and to maintain competitive advantages through innovation and quality.

The upcoming 138th Canton Fair presents a significant opportunity for exhibitors in the manufacturing sector, especially for those specializing in end mill bits. According to a report by Mordor Intelligence, the global end mill market was valued at approximately $2.2 billion in 2022 and is expected to grow at a CAGR of 6.1% over the next few years. This growth reflects an increasing demand for high-precision machining tools in various industries, including automotive and aerospace. The Canton Fair, being one of the largest trade events, offers a platform for manufacturers to showcase their innovations, connect with international buyers, and expand their market reach.

Exhibitors can leverage this platform to tap into the growing global interest in advanced manufacturing technologies. The fair attracts thousands of buyers from around the world, providing a unique chance to engage directly with decision-makers and industry influencers. As businesses increasingly focus on automation and efficiency, the demand for top-quality end mill bits is poised to rise, making this an opportune moment for manufacturers to highlight their offerings. With the fair's strategic location in China, known for its robust manufacturing capabilities, exhibitors can effectively position themselves amidst the competition while benefiting from China's established supply chain networks.

As the 137th Canton Fair approaches, the spotlight shines on China's leading end mill bit manufacturers, particularly in the context of the nation's ambitious targets for renewable energy consumption by 2025. The government's new renewable energy plan indicates a significant shift in industrial capabilities, which will likely influence the production and design of cutting tools like end mill bits. Manufacturers are expected to leverage this momentum to innovate their product offerings, aligning with the growing demand for precision machining driven by advancements in industries such as automotive and aerospace.

Moreover, the carbide tools market, projected to flourish in the next decade, highlights the strategic importance of high-performance cutting tools in various sectors. As China's manufacturing capabilities evolve, end mill bit producers are increasingly integrating advanced technologies into their processes. This progressive approach not only enhances efficiency but also positions them as competitive players in the global market. The growing emphasis on innovation and eco-friendly practices suggests that these manufacturers will be key drivers of change, setting the stage for a transformative decade ahead.

| Rank | Manufacturer Type | Annual Production Capacity (Units) | Main Export Markets | ISO Certification |

|---|---|---|---|---|

| 1 | High-Speed Steel | 500,000 | North America, Europe | ISO 9001 |

| 2 | Carbide | 300,000 | Asia, Australia | ISO 9001, ISO 14001 |

| 3 | Cobalt | 450,000 | Europe, Middle East | ISO 9001, TS 16949 |

| 4 | Diamond Coated | 600,000 | North America, Europe | ISO 9001 |

| 5 | Plain | 550,000 | South America, Asia | ISO 9001, OHSAS 18001 |

| 6 | Specialty Tools | 400,000 | Europe, Australia | ISO 9001 |

| 7 | End Mill Insert | 350,000 | North America, Middle East | ISO 9001, ISO 14001 |

| 8 | Tapered End Mills | 250,000 | Asia, South America | ISO 9001 |

| 9 | Ball Nose | 300,000 | Australia, Europe | ISO 9001, TS 16949 |

| 10 | End Mill Sets | 200,000 | North America, Asia | ISO 9001 |