In the rapidly evolving world of woodworking and carpentry, achieving precision is paramount for delivering high-quality results. According to a report by the American Woodworking Association, over 70% of woodworkers cite the accuracy of their tools as a critical factor influencing their work quality. With intricate designs and detailed craftsmanship becoming standard expectations, the demand for tools that enhance precision has surged. Among these, the best router bits stand out as essential components that can significantly impact the final product's detail and finish.

Moreover, a recent study from the Association of Woodworking Professionals highlighted that investing in high-quality router bits can improve efficiency and reduce waste by nearly 30%. This shift towards precision-oriented tools exemplifies the industry's commitment to innovation and quality. As woodworkers continually seek ways to refine their craft, understanding the dynamic landscape of router bits, including their types and applications, is vital. In this blog, we will explore innovative products that promise to elevate your woodworking precision and help you choose the best router bits for your projects.

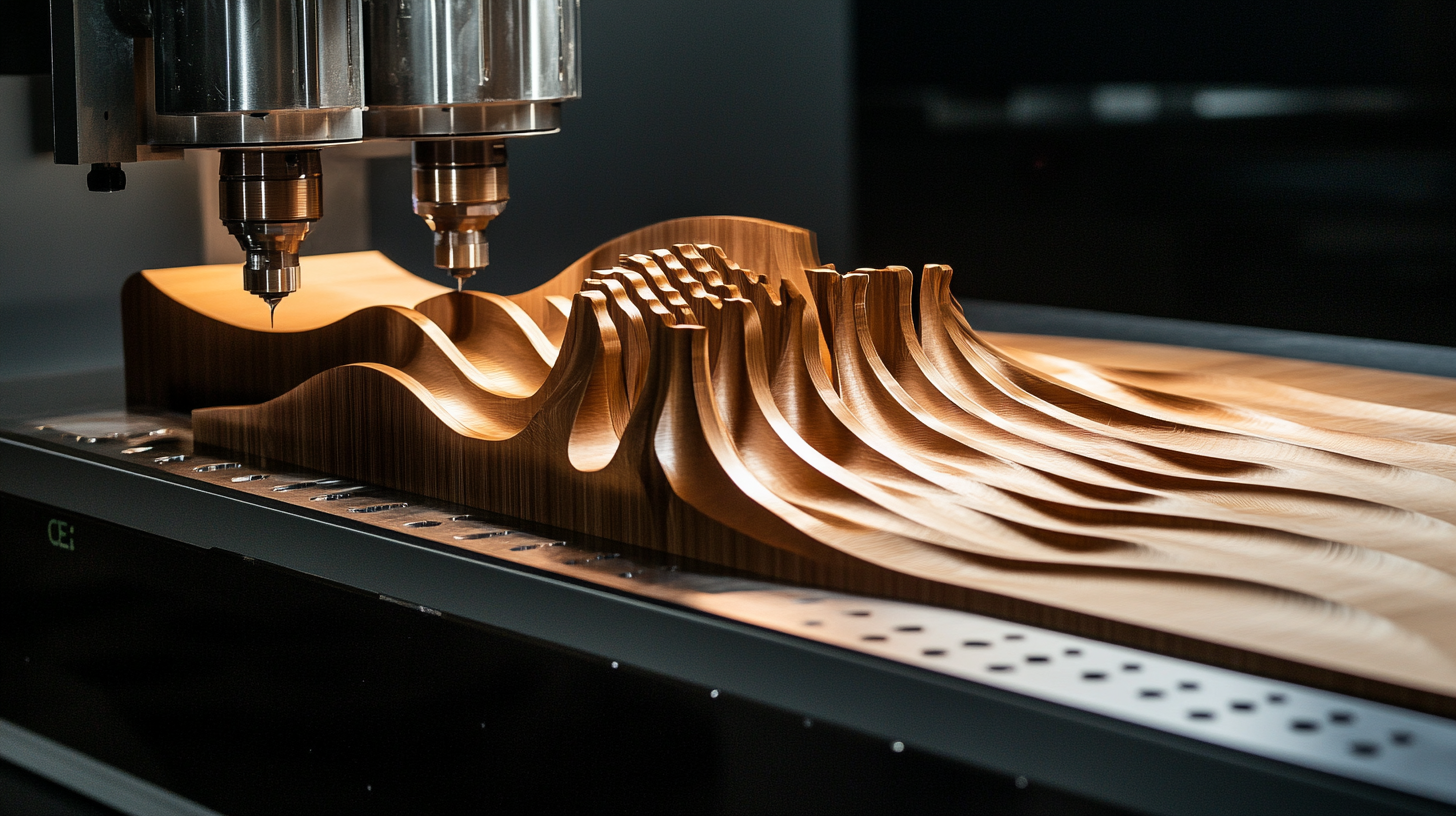

The woodworking industry has witnessed a remarkable transformation with the introduction of innovative router bit designs that significantly enhance precision. Today's router bits are not just functional tools; they are meticulously engineered to meet the specific needs of woodworkers, from amateurs to seasoned professionals. Advanced materials and cutting-edge manufacturing processes have given rise to router bits that deliver cleaner cuts, reduced friction, and improved durability. Whether it's a flush trim bit or a spiral up-cut bit, these innovations ensure that every cut is executed with unmatched accuracy. The intricate designs of modern router bits play a crucial role in achieving superior results. For instance, spiral bits with their unique helical flutes provide better chip removal and allow for smoother cuts in hard materials. Such designs reduce the likelihood of burning the wood and ensure a flawless finish. Additionally, features like micro-grain carbide tips enhance the longevity of the bits, enabling woodworkers to maintain precision over extended use without frequent replacements. These advancements empower craftsmen to push the boundaries of their creativity while maintaining the high-quality standards expected in the woodworking craft. Moreover, the customization of router bits has also become a game-changer. Woodworkers can now select bits based on their unique project requirements, allowing for versatile applications—from intricate carvings to complex joints. This level of personalization not only streamlines the woodworking process but also enhances craftsmanship by providing the right tool for the right job. As innovative router bit designs continue to evolve, they are setting new standards for precision in woodworking, inspiring artisans to explore new possibilities in their craft.

When it comes to achieving precision in woodworking, the importance of router bit geometry cannot be overstated. The shape and design of a router bit directly influence the cutting accuracy and finish quality of the workpiece. According to a report by the Woodworking Machinery Industry Association (WMIA), up to 40% of machining errors can be traced back to inadequate bit geometry. This highlights the significance of choosing the right bit for specific applications.

For instance, the angle of the cutter affects the shear force applied to the material, which can lead to cleaner cuts and less tear-out when working with delicate woods. Research from the American Woodworking Institute (AWI) indicates that a 10-degree increase in the cutting angle can improve the surface finish by as much as 25%. Additionally, the profile of the router bit plays a crucial role; spiral bits, for example, often produce superior results in composite materials due to their design, which promotes a smoother entry and exit from the material.

Furthermore, considering the material composition of the bits themselves is essential in enhancing durability and performance. A study by the International Journal of Wood Technology revealed that carbide-tipped router bits last up to three times longer than high-speed steel bits before dulling, ultimately improving cost-effectiveness and ensuring precision in production processes. Therefore, understanding the impact of bit geometry is not just a matter of theory but a practical necessity for achieving the highest standards in woodworking.

The landscape of woodworking has evolved significantly with technological advancements in router bit materials, offering a range of benefits that enhance precision and efficiency in projects. Modern router bits are often engineered from high-grade materials such as carbide and cermet, which exhibit superior hardness and resistance to wear. This improved durability allows for a longer lifespan of the bits, reducing the frequency of replacements and providing better value for both hobbyists and professionals alike.

In addition to improved materials, innovations such as optimized cutting geometries have also revolutionized router bits. Advanced designs, including spiral and dovetail patterns, enable smoother cuts and finer finishes, while minimizing the risk of chipping and splintering in various types of wood. These enhancements not only improve the quality of the finished product but also reduce the time spent on each project, making woodworking a more enjoyable and efficient endeavor.

Furthermore, the advent of coatings such as titanium nitride and diamond has further elevated the capabilities of router bits. These coatings provide additional protection against heat and friction, enhancing performance in high-speed applications. As a result, woodworkers can expect cleaner cuts and less heat buildup, which helps preserve the integrity of the materials being worked on. The combination of these advanced materials and cutting-edge designs ensures that today's router bits are not just tools, but essential partners in achieving precision and excellence in woodworking projects.

When it comes to achieving precision in woodworking, selecting the right router bit is paramount. Numerous industry reports underscore the importance of precision tools in improving overall craftsmanship. For instance, a study by the American National Standards Institute (ANSI) indicated that using high-quality router bits can enhance cut accuracy by up to 25%, significantly reducing the need for post-processing adjustments.

One key factor in choosing the right router bit is the material it is made of. Carbide-tipped bits are preferred for their longevity and ability to maintain sharp edges, making them ideal for precision work in harder woods. According to data from the Woodworking Machinery Industry Association (WMIA), 70% of professional woodworkers report using carbide bits for their projects, highlighting their essential role in achieving accurate results.

Another crucial aspect to consider is the router bit geometry. The design of the cutting edge can influence the quality of the finished product. Research from the Association of Woodworking Professionals (AWP) emphasizes that spiral bits, for example, can provide cleaner cuts and reduced tear-out compared to straight bits, particularly in delicate projects. Selecting the right geometry can thus substantially impact the precision and aesthetic quality of the final piece.

Ultimately, understanding these key factors—material composition and bit geometry—is essential for woodworkers aiming for precision in their projects. By investing in the right router bits, craftsmen can elevate their work quality and meet the rigorous standards set in the industry.

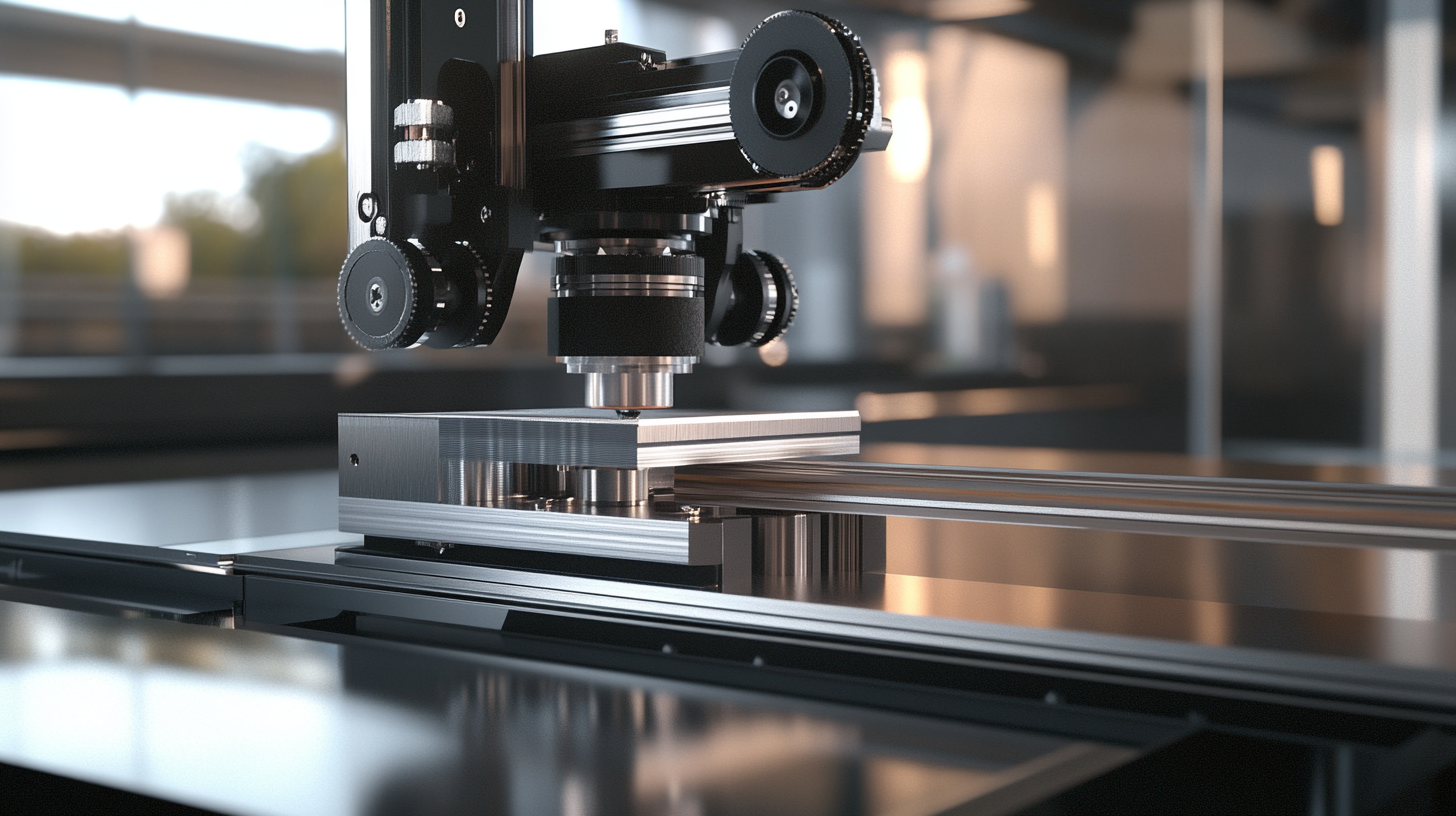

The demand for high-precision router bits is closely aligned with the significant growth of the global woodworking machinery market, which was valued at USD 4.86 billion in 2023 and is projected to reach USD 7.77 billion by 2030. This expansion reflects a stronger emphasis on quality and precision in woodworking, driven by evolving consumer expectations and advancements in technology. As manufacturers strive for excellence, the need for precision tools like router bits becomes paramount.

The CNC router machine market similarly showcases robust growth potential, estimated at USD 691.0 million in 2023 and expected to grow at a CAGR of 3.5% from 2024 to 2030. This growth underscores the increasing role that CNC technology plays in enhancing precision in woodworking. As industries adopt more sophisticated machinery, the requirement for high-quality router bits that can deliver accuracy and consistency becomes even more critical.

Moreover, with the woodworking CNC tools market anticipated to rise from USD 8.2 billion in 2025 to USD 13.3 billion by 2035, the trend towards high-precision router bits is expected to accelerate. This growth trajectory highlights the evolving landscape of woodworking, where consumers and professionals alike are seeking innovative solutions that leverage advanced technologies for improved outcomes. The integration of cutting-edge tools and techniques continues to transform the woodworking sector, paving the way for enhanced productivity and superior craftsmanship.