In the world of packaging and printing, the Lamination Machine plays a critical role. Recent industry reports indicate that the global market for lamination machines is expected to grow at a compound annual growth rate of over 5% by 2026. This growth highlights the increasing demand for high-quality laminated products. However, achieving optimal performance and durability requires careful consideration of various factors.

Operators often overlook basic maintenance procedures, which can lead to significant issues down the line. For instance, according to a study published by the International Journal of Production Research, improper temperature settings can lead to poor lamination quality. This, in turn, affects the product’s appearance and usability. Additionally, understanding the type of laminating films used is crucial. Different films can produce varying results, impacting overall production efficiency.

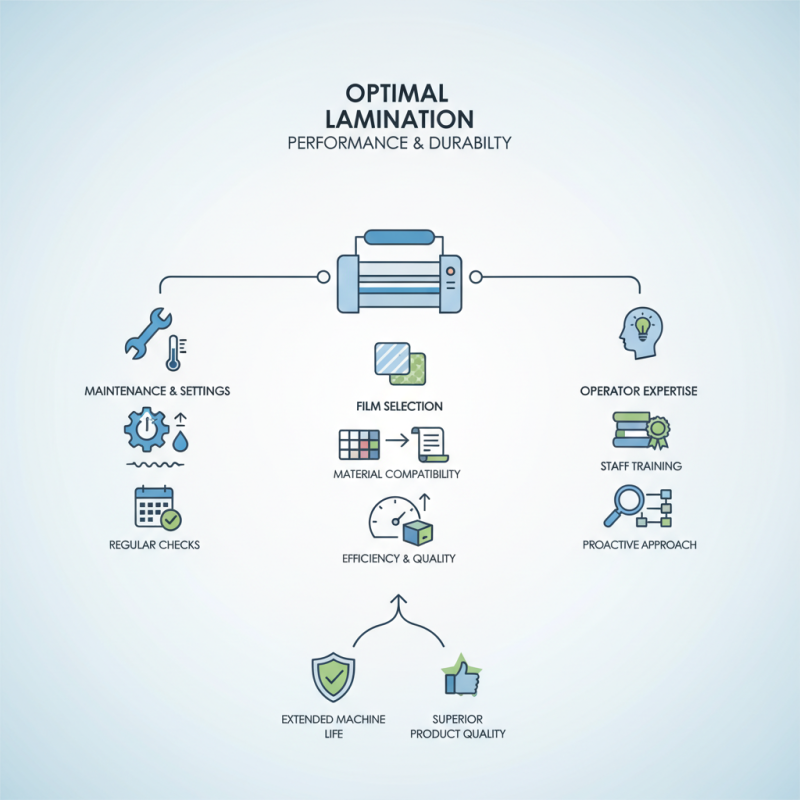

Attention to detail is necessary for improving lamination processes. Investing time into staff training can reduce waste and enhance output. Laminating machines can be complex and demand regular assessment. However, many operators tend to rely on outdated methods, limiting their potential. Developing a proactive approach can ultimately lead to achieving better performance and extended machine life.

Lamination machines are crucial in various industries. They protect documents and enhance their appearance. Understanding how these machines work can boost their performance. This guide covers the basics of lamination.

Lamination machines use heat and pressure to bond layers together. The process usually involves thermal films. The key is to select the right film for your project. Incorrect film can lead to bubbling or peeling. Some users overlook this detail. Moisture can also affect lamination quality. Ensure your documents are dry before laminating.

Adjusting the settings is vital for optimal results. Many users fail to do this. Temperature and speed must match the type of material used. Laminating thicker sheets often requires more heat. It's a balancing act that needs practice. Keep records of successful runs. Testing with scrap materials can save wastage. Even seasoned operators might need to refine these skills.

When selecting a high-quality lamination machine, it's essential to consider several key features. One crucial aspect is the laminating speed. Fast machines, capable of laminating 10 to 15 feet per minute, can significantly enhance productivity. However, too much speed can lead to mistakes, affecting the final quality. Users must find a balance between speed and precision.

Another important feature is the heating system. Machines with advanced heating elements provide consistent results. These machines usually have a warm-up time of under 10 minutes. Yet, some users report issues with uneven heat distribution, which can lead to bubbling or wrinkling of materials. Regular maintenance can help, but it does require user diligence.

Additionally, the versatility of a lamination machine cannot be overlooked. Being able to handle various thicknesses is essential for accommodating different projects. Many models allow for films ranging from 1.5 to 10 mils. But operators often face challenges when switching between film types. This can disrupt workflow and lead to wasted materials. Knowledge of machine specifications is vital for reducing errors and maximizing efficiency.

| Feature | Description | Importance |

|---|---|---|

| Heat Settings | Adjustable temperature controls for different materials. | Ensures proper lamination without damaging materials. |

| Speed Control | Variable speed settings for customized lamination speed. | Improves efficiency and ensures quality output. |

| Roller Quality | Durable rollers that resist wear and ensure smooth operation. | Increases the lifespan of the machine and quality of lamination. |

| Safety Features | Emergency shut-off and heat shields. | Protects users and equipment from accidents. |

| Size and Capacity | Dimensions and thickness of materials that can be laminated. | Determines suitability for various projects. |

| User-Friendliness | Intuitive controls and easy setup. | Reduces training time and increases productivity. |

Maintaining a lamination machine is crucial for optimal performance and longevity. Regular cleaning is essential. Dust and residue can build up, affecting the quality of lamination. Use a soft cloth to wipe down the surfaces. Check the rollers for any debris. A clean machine works better and more efficiently.

Another important tip is to monitor the temperature settings. Running the machine too hot can damage materials. Conversely, too low a temperature might lead to poor adhesion. Striking a balance is key. Adjust settings according to the type of films used. Keep a log of your adjustments to track what works best.

Don't overlook the importance of proper storage. A dry, cool place is ideal. Extended exposure to humidity can warp materials. Store films away from direct sunlight. Make note of expiration dates for supplies. Even seemingly minor details can impact overall performance and durability. Regular reflection on these practices will ensure a lamination machine thrives in any environment.

Lamination machines are invaluable for protecting documents, but they can encounter common issues. Knowing how to troubleshoot is essential for maintaining optimal performance.

One frequent problem is sealing failure. When the film does not adhere properly, it can lead to bubbles or wrinkles. This often happens due to improper temperature settings. It’s crucial to regularly check the machine’s temperature calibration. If the film is too thick for the machine, it may not seal well. Test different thicknesses to find the right fit.

Another common issue is a paper jam. This can occur when improperly sized documents are used. Always ensure the paper size matches the machine specifications. If a jam happens, turn off the machine first. Clear the jam carefully to avoid damaging the rollers. A gentle approach is key here; sometimes, rushing can worsen the situation.

For optimal use, consider cleaning the machine regularly. Dust and residue can accumulate and lead to malfunctions. A simple cleaning routine can prolong the machine’s life. Remember, frequent inspections can catch minor issues before they become larger problems.

Laminating different materials requires specific techniques for the best results. For example, using thicker laminating pouches on dense materials like cardstock is essential. This extra thickness protects against moisture and wear.

When working with heat-sensitive materials, such as photos or specialty papers, a lower temperature setting on the laminating machine works well. It prevents damage and ensures a smooth finish. Skipping this step can lead to wrinkles or peeling edges.

Users often overlook the importance of cleaning the machine regularly. Dust and adhesive residue may cause uneven layers. Take a moment to inspect the rollers after each use. If they are dirty, the binding quality may decline. Regular maintenance goes a long way in achieving optimal performance.