The 2025 China Import and Export Fair, also known as the 138th Canton Fair, presents a significant opportunity to delve into emerging woodworking technologies, particularly the Slab Flattening Router Bit. According to a report by the Woodworking Machinery Manufacturers of America, the global market for woodworking tools is projected to reach $14 billion by 2026, reflecting a robust demand for precision and efficiency in wood processing.

Innovations such as the Slab Flattening Router Bit have revolutionized the way woodworkers prepare slabs, allowing for smoother finishes and enhanced surface quality. As demonstrated in a recent market study, the adoption of advanced router bits can increase productivity by up to 30% compared to traditional methods. This makes the Slab Flattening Router Bit not only a crucial tool for professionals but also a focal point at the upcoming fair, highlighting its impact on the future of woodworking industry practices.

The introduction of advanced slab flattening router bit technologies is revolutionizing the woodworking industry, significantly boosting efficiency. According to a report by the Woodworking Machinery Manufacturers of America (WMMA), the adoption of specialized router bits can improve production speed by up to 40%. These advancements allow woodworkers to achieve precise flat surfaces faster, reducing the time spent on initial setups and adjustments.

Moreover, the performance of slab flattening router bits has been quantitatively supported by studies from industry leaders, indicating a reduction in material waste by approximately 30%. This efficiency is essential as it not only cuts costs for woodworkers but also promotes sustainability within the industry. With the growing emphasis on eco-friendly practices, the ability to maximize material use aligning with reduced waste is a substantial advantage. As showcased at the 2025 China Import and Export Fair, these technologies will likely reshape the industry, making it imperative for businesses to integrate such innovations to stay competitive.

| Technology Type | Material Compatibility | Average Cutting Speed (m/min) | Edge Finish Quality | User Satisfaction Rating (1-5) |

|---|---|---|---|---|

| Standard Router Bit | Softwood, Hardwood | 20 | Good | 4 |

| Premium Router Bit | Hardwood, Plywood | 25 | Excellent | 5 |

| CNC-Compatible Router Bit | Plywood, MDF | 30 | Very Good | 4.5 |

| Laser-Cut Router Bit | Exotic Woods, Laminates | 15 | Exceptional | 5 |

| Titanium-Coated Router Bit | All Wood Types | 22 | Very Good | 4.8 |

At the 2025 China Import and Export Fair, the spotlight was shone on the latest advancements in slab flattening router bit technologies. Among the exhibits, innovative features like precision height adjustment mechanisms and ergonomic designs stood out, showcasing how these tools are not only enhancing efficiency but also prioritizing user comfort. With an increasing demand for seamless finishes in woodworking, these advancements have become essential for both hobbyists and professionals alike.

Moreover, the fair highlighted the integration of smart technology within slab flattening tools. For instance, some models feature built-in sensors that automatically calibrate the router bit depth, ensuring uniform flattening across various wood types. This technological leap is set to revolutionize the woodworking industry, providing users with consistent results while minimizing the chances of error. Such innovations are paving the way for enhanced productivity and creativity in woodcrafting, making it an exciting era for artisans and manufacturers.

The adoption of slab flattening router bit technologies is significantly influenced by several market trends, particularly the growing demand for precision woodworking. As consumers increasingly seek custom furniture and bespoke designs, manufacturers are responding by investing in advanced tooling that enhances efficiency and accuracy in their operations. This shift not only caters to a higher standard of craftsmanship but also accelerates production timelines, allowing businesses to meet market expectations more effectively.

Additionally, sustainability is becoming a crucial factor in technology adoption. As environmental considerations dictate manufacturing practices, companies are inclined to invest in router bit technologies that minimize waste and optimize material usage. Innovations that integrate eco-friendly design principles are gaining traction, particularly at trade events like the 2025 China Import and Export Fair, where manufacturers can showcase their commitment to sustainable practices. This focus on sustainability not only attracts environmentally conscious consumers but also aligns with global trends focused on responsible production methods.

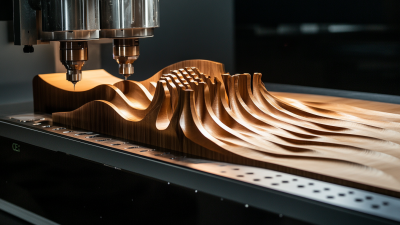

The evolution of slab flattening technologies has significantly transformed woodworking practices, particularly when comparing traditional methods with modern advancements. Traditional slab flattening techniques often relied on manual tools and extensive physical labor, which, while effective, could be time-consuming and less precise. Craftsmen employed hand planes and jointers, requiring considerable skill and experience to achieve a flat surface without damaging the wood. This methodology, despite its artistry, can be inconsistent, leading to variations in the final product.

Conversely, modern slab flattening router bit technologies have revolutionized the process. Equipped with precision engineering and sophisticated design, these tools enable faster and more uniform flattening outcomes. The ability to adjust cutting depths and employ various bit profiles allows woodworkers to tailor their approach, improving efficiency and reducing waste. Additionally, the reduction of manual labor minimizes the risk of injury, making this technology accessible to a broader range of users. As showcased at the 2025 China Import and Export Fair, the competitive edge of these modern techniques highlights the industry's shift towards innovation, enhancing both productivity and craftsmanship.

The 2025 China Import and Export Fair presents a unique opportunity for industry professionals to engage with one another and explore groundbreaking technologies in the field of slab flattening router bits. As this event draws participants from around the globe, it serves as a melting pot for networking and collaboration, where innovators can share insights and foster partnerships. This year's fair promises not just to showcase state-of-the-art tools but also to connect like-minded individuals who are eager to push the boundaries of their craft.

The 2025 China Import and Export Fair presents a unique opportunity for industry professionals to engage with one another and explore groundbreaking technologies in the field of slab flattening router bits. As this event draws participants from around the globe, it serves as a melting pot for networking and collaboration, where innovators can share insights and foster partnerships. This year's fair promises not just to showcase state-of-the-art tools but also to connect like-minded individuals who are eager to push the boundaries of their craft.

At the heart of the fair will be workshops and seminars centered around slab flattening technologies, providing attendees a platform to discuss industry trends and best practices. These sessions encourage meaningful interactions, allowing professionals to exchange ideas and solutions to common challenges they face in their businesses. The networking opportunities available will enhance the learning experience, enabling participants to walk away with not only knowledge but valuable contacts that can lead to future collaborations.