In the rapidly evolving landscape of manufacturing, the choice of cutting tools has a significant impact on operational efficiency and product quality. According to a report by The Freedonia Group, the global market for cutting tools is projected to reach $24 billion by 2026, driven by advancements in technology and the growing need for precision in production. As industries increasingly adopt automation and lean manufacturing principles, the demand for advanced cutting tools that enhance productivity and reduce waste becomes critical. Companies that invest in high-performance cutting tools not only experience improved machining accuracy but also enjoy longer tool life and reduced downtime. In this blog, we will explore seven compelling reasons why your business must embrace advanced cutting tools to stay competitive and meet the challenges of modern manufacturing.

In the competitive landscape of modern manufacturing, precision plays a critical role in determining product quality and operational efficiency. According to a recent report by the National Association of Manufacturers, 82% of manufacturers believe that precision engineering is vital for maintaining competitiveness in the global market. As businesses strive to meet rising consumer expectations and stringent regulatory standards, the need for advanced cutting tools becomes clear. These tools enable manufacturers to achieve tighter tolerances and superior finishes, which directly translates to lower defect rates and reduced waste.

Furthermore, a study by the Precision Machined Products Association reveals that implementing advanced cutting technology can improve productivity by up to 30%. This increase not only enhances throughput but also contributes to significant cost savings. High-precision cutting tools facilitate complex geometrical shapes and intricate designs, allowing manufacturers to innovate and meet bespoke client demands seamlessly. As industries evolve and embrace automation and smart manufacturing, the integration of cutting-edge tools becomes indispensable for driving precision and quality, ultimately elevating a company's reputation in the marketplace.

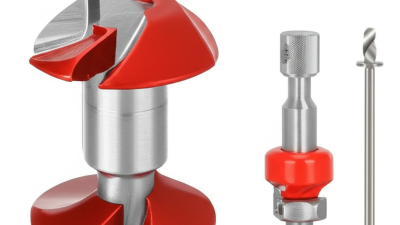

Advanced cutting tools are revolutionizing the way businesses operate, significantly enhancing efficiency and productivity across various industries. These tools offer precision and speed that traditional methods simply cannot match. By employing advanced materials and innovative designs, they reduce friction and wear, allowing for smoother cutting processes. This not only minimizes downtime for tool changes but also leads to faster production cycles. As a result, companies can meet increasing market demands without sacrificing quality.

Moreover, integrating advanced cutting tools into manufacturing processes can lead to substantial cost savings. The ability to cut materials more accurately means less waste, reducing costs associated with excess material and post-processing. Enhanced cutting efficiency also translates to lower power consumption, further optimizing operational costs. When businesses invest in upgrading to these state-of-the-art tools, they position themselves for sustained competitive advantage, ensuring that they can deliver products more quickly and reliably than their competitors. This proactive approach to productivity can be the key differentiator in today’s fast-paced market.

Investing in advanced cutting tools can significantly enhance the cost-effectiveness of your business operations. While the initial expenses might seem high, the long-term savings that come with superior cutting solutions are undeniable. Advanced tools are designed for precision and durability, allowing for faster production cycles and reduced waste. This means you can achieve more with less material, cutting down on both consumption and expense.

Moreover, the efficiency of these cutting tools often leads to lower labor costs. When your machinery works seamlessly, it minimizes the time employees spend on each task. This not only increases productivity but also enables your workforce to focus on more value-added activities, enhancing the overall output of your business. In a competitive market, these factors accumulate to substantial savings, making advanced cutting tools a smart investment for any forward-thinking organization.

In today's rapidly evolving industrial landscape, versatility and adaptability are paramount for businesses aiming to meet diverse industry needs. Advanced cutting tools exemplify this necessity, as they enable manufacturers to tackle a wide range of materials and functions, thereby driving efficiency and innovation. Just as graduates entering the workforce are encouraged to develop a versatile skill set to thrive in non-academic environments, businesses must invest in tools that provide multifunctional capabilities.

For instance, the recent introduction of flexible industrial cleaning solutions highlights the importance of adaptability in equipment design. Companies like those enhancing their conveyor systems and expanding their product ranges demonstrate that the ability to address various requirements is key to staying relevant.

This trend is reflected across multiple sectors, from automation needing to integrate more diverse technologies to software development that requires programmers to be proficient in multiple languages. Advanced cutting tools serve as a crucial element in this ecosystem, allowing organizations to shift seamlessly in response to changing market demands and pushing the boundaries of what can be achieved in manufacturing and production processes.

In the realm of material science, advanced cutting tools

are becoming increasingly integral to the development and manipulation of innovative materials. The recent advancements in additive manufacturing, particularly through directed energy deposition techniques, are revolutionizing how cutting tools are designed and utilized. These sophisticated processes allow for the production of tools that can better meet the rigorous demands of high-performance applications, thereby enhancing efficiency and precision in manufacturing.

Moreover, the intersection of artificial intelligence and materials science is fostering the creation of purpose-driven materials. By leveraging AI, researchers are able to accelerate the identification of new materials with specific properties, which in turn can be used to manufacture cutting tools that are not only robust but also versatile.

This two-way relationship underscores the essential role advanced cutting tools play in pushing the boundaries of what's possible in material innovation—whether it’s optimizing operations in existing industries or paving the way for breakthroughs in emerging fields. As businesses navigate these complexities, investing in advanced cutting tools will become increasingly paramount for maintaining a competitive edge.