In the ever-evolving world of drilling technology, the Reamer Drill Bit stands out as a vital tool. This bit typifies efficiency, precision, and reliability. Industry reports indicate that the global market for reamer drill bits is projected to grow by 5% annually. Such growth underscores their significance in various applications, from construction to oil drilling.

Many professionals recognize the key features of modern Reamer Drill Bits, such as their ability to improve hole quality and reduce wear. A recent study revealed that using advanced materials in drill bits can enhance durability by up to 30%. Moreover, these bits are designed to handle complex geological conditions effectively. The balance between performance and cost remains a critical consideration for users.

However, not all Reamer Drill Bits are created equal. Understanding their benefits and limitations is essential for making informed decisions. The industry's shift toward customization may also prove challenging for some. Ultimately, while these drill bits offer superior features, ongoing evaluation and adaptation are necessary for optimal results.

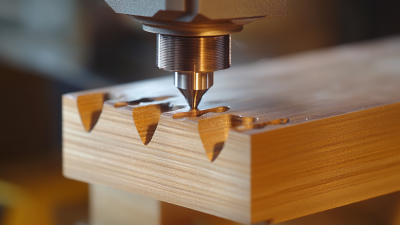

The 2026 Top Reamer Drill Bits showcase several critical features. These bits are designed for enhancing drilling efficiency. Their unique shape allows for smoother operations in various materials. Users have noted that they provide better precision and control during drilling tasks. This precision helps to reduce wear on the drill bit itself.

Another key feature is their durability. Made from high-quality materials, these drill bits resist wear and tear. Users report that they last longer than standard bits. This longevity can lead to cost savings over time. However, some professionals believe they can be challenging to use for less experienced drillers. The learning curve may require additional practice.

The design also includes advanced cutting geometry. This allows for quick penetration and reduced energy consumption. Many users appreciate the reduced friction. It is important to consider the specific use case. While they excel in some scenarios, they may underperform in others. Balancing the benefits and limitations is essential for optimal use.

Advanced reamer drill bits offer numerous benefits that significantly enhance drilling operations. These tools are designed to create precise holes with smooth finishing. Their advanced engineering allows users to reduce friction and improve cutting efficiency. Consequently, operators can achieve faster drilling speeds, saving both time and resources.

The use of these sophisticated drill bits also leads to a decrease in wear and tear. This is crucial, as frequent replacements can hinder project timelines and inflate costs. Moreover, advanced reamer drill bits often produce less material waste, making them more environmentally friendly. However, it’s essential for users to recognize that not every project may require such high-end tools.

Some challenges remain in the adoption of advanced reamer drill bits. For instance, the initial investment can be higher than traditional alternatives. Not considering the specific needs of a project may lead to regrettable choices. Identifying the right tool for the job is vital. Using a bit that isn’t suitable can result in poor performance. Thus, a thoughtful approach is essential when selecting the proper reamer drill bit.

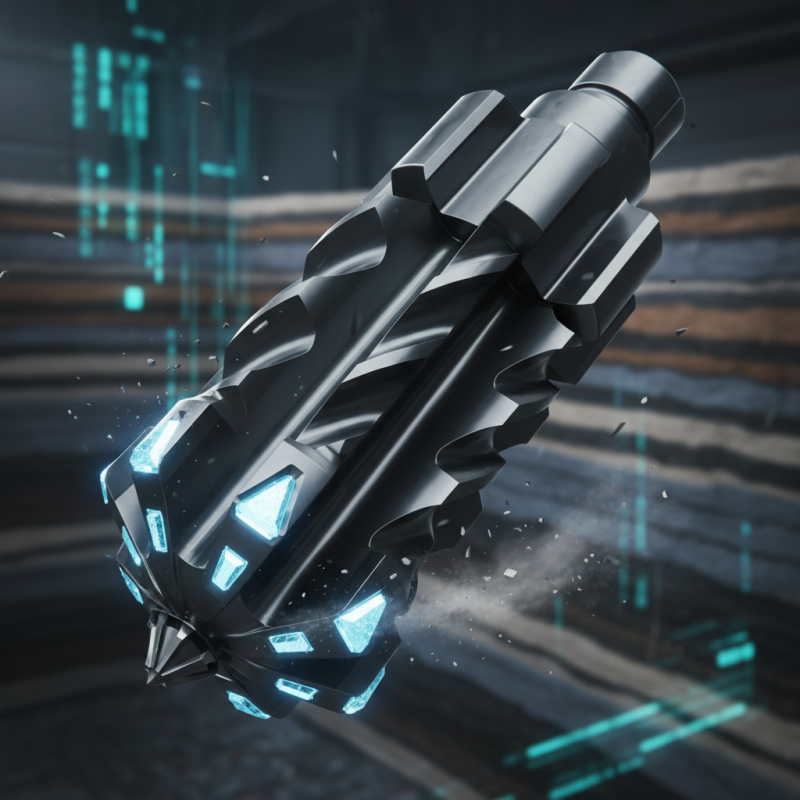

The 2026 reamer drill bits stand out significantly when compared to previous models. Enhanced design features improve precision during drilling. These new bits have optimized cutting edges that allow for smoother finishes. Operators notice a reduction in vibration and noise, which can improve fatigue levels.

While the innovations are impressive, some aspects require careful evaluation. Not all users have found these latest bits compatible with every existing drill model. Additionally, there may be a learning curve for those accustomed to older bits. The materials used, though advanced, may not perform as expected in all conditions. Variability in user experience can prompt further consideration on the best applications for these bits.

The benefits are clear, yet challenges exist. Users often report about premature wear in specific applications. It raises questions about longevity under rigorous use. As these bits gain traction in the market, more feedback can refine our understanding. Insights gathered from daily use will inform future improvements. Understanding both strengths and weaknesses fosters better selection for professional needs.

Reamer drill bits play a crucial role in various industries, particularly in manufacturing and construction. These tools are designed to create precise holes and improve the size and finish of existing holes. Data from industry reports indicate that the global demand for reamer drill bits is expected to grow at a CAGR of 4.5% from 2023 to 2028. This reflects their essential function in achieving accuracy and efficiency in drilling operations.

In the automotive sector, reamer drill bits are integral to engine assembly and components fitting. They ensure the proper alignment and sizing necessary for high-performance vehicles. Similar applications are found in aerospace, where reaming contributes to the safety and reliability of aircraft components. However, there is a need for manufacturers to adopt advanced materials and coatings that provide durability. Some reports suggest that only a small percentage of companies utilize the latest technologies in reamer production.

Construction industries also benefit from reaming tools, especially when dealing with concrete and masonry. These bits help achieve smoother finishes and better fit for reinforcements. Yet, challenges persist. Some companies fail to regularly maintain their tools, leading to reduced performance and increased costs. A proactive approach to tool management could significantly enhance productivity and accuracy in projects.

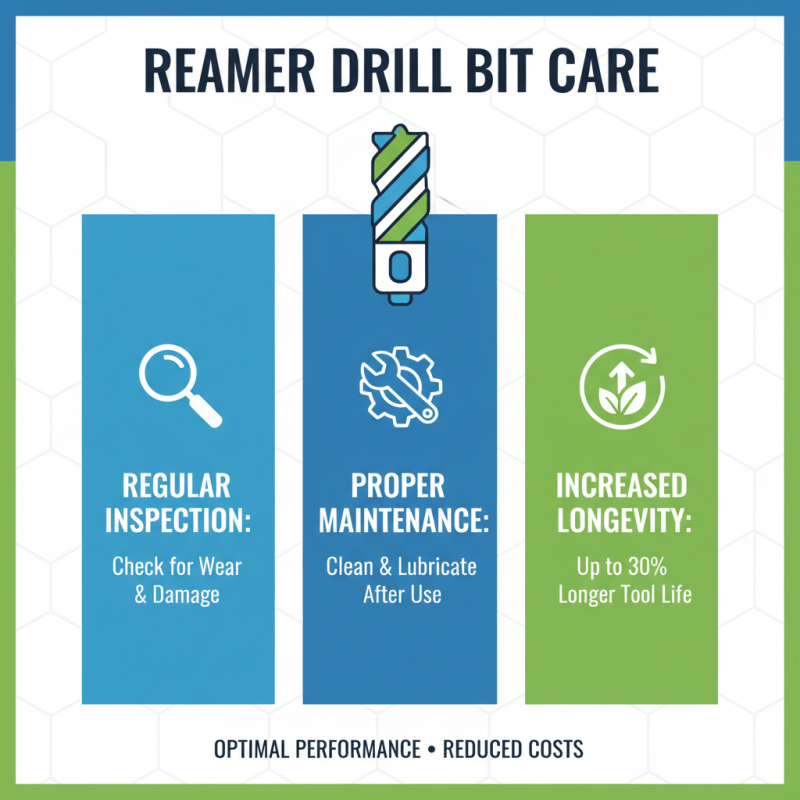

Proper maintenance of reamer drill bits is crucial for optimal performance and longevity. Studies show that well-maintained drill bits can last up to 30% longer than those that are not cared for. Regular inspection is vital. Check for wear and tear frequently. Look for signs like chipping or dullness. Minor issues can escalate quickly if ignored.

Cleaning your reamer bits after each use is essential. A mixture of warm water and mild detergent can help remove debris. Residue can cause overheating during drilling. High temperatures wear down bits much faster. Also, lubricating your drill bits with a suitable oil improves performance. This step reduces friction and minimizes wear.

Storing your reamer drill bits properly is often overlooked. Keep them in a dry, cool location. Avoid stacking them haphazardly as this can lead to damage. An organized storage system can prevent accidents and prolong their lifespan. According to the National Center for Advanced Manufacturing, organized storage can reduce the risk of accidental damage by 50%. Keeping these tips in mind can help maintain your equipment effectively.